CTE-4016-5V200A

Regenerative Battery Testing System

Application: Power cell formation, grading and cycle life testing; Advantages: Improving energy utilization efficiency and reducing production energy consumption. Mainly support: Battery manufacturers, new energy vehicle manufacturers.

-

Space

Space

reduce 30% -

Electricity Fees

Electricity Fees

reduce 30% per year -

Calorific Value

Calorific Value

reduce 50% -

Energy Consumption

Energy Consumption

reduce 50%

- Full bridge buck\boost circuit topology, discharge voltage lower to 0V

- The core processor adopts 32bit DSP and supports floating-point operation

- Bidirectional smart DCAC inventor adopts high frequency rectifier reversible SMR technology. It has realized high power factor harmonics and ensured power quality

- AD16bit,DA14bit,Temperature drift of the core device is less than 50ppm

- Modular design and fast plug connector that is used for current and voltage is easy for us to upgrade and maintain

- Bidirectional smart DCDC converter adopts synchronous rectification technology

- Save>50%/YearElectricity Fees

- Reduce50%Energy Consumption

- Reduce50%Calorific Value

- Reduce30%Floor Space

High Efficiency Energy-feedback Battery Testing System

Customized for 5V formation and Grading Battery Testing System

- 1Bidirectional smart DCDC converter adopts synchronous rectification technology and 32-bit high-speed DSP processor with floating-point operation, so that not a single energy conversion leaks out;

- 2In order to make sure power grid quality, bidirectional smart DCAC inventor adopts high frequency rectifying reversible SMR technology to realize high power factor and low harmonic;

- 3It can significantly reduce factory environmental temperature, save energy consumption, and reduce floor space. What's more, it can also improve the products' cost performance.

General Trend→Energy-feedback Battery Testing System.

Application: Power cell formation, grading and cycle life testing; Advantages: Improving energy utilization efficiency and reducing production energy consumption. Mainly support: Battery manufacturers, new energy vehicle manufacturers.

-

Bidirectional DCDC Modular

Bidirectional DCDC Modular

-

Bidirectional AC/DC Power Supply

Bidirectional AC/DC Power Supply

Full Sine Wave Feedback, Low Harmonic, High Power Factor, High Efficiency

In order to meet CELL, MODULE and PACK testing requirements in different fields, NEWARE has launched three wide range bus solutions.

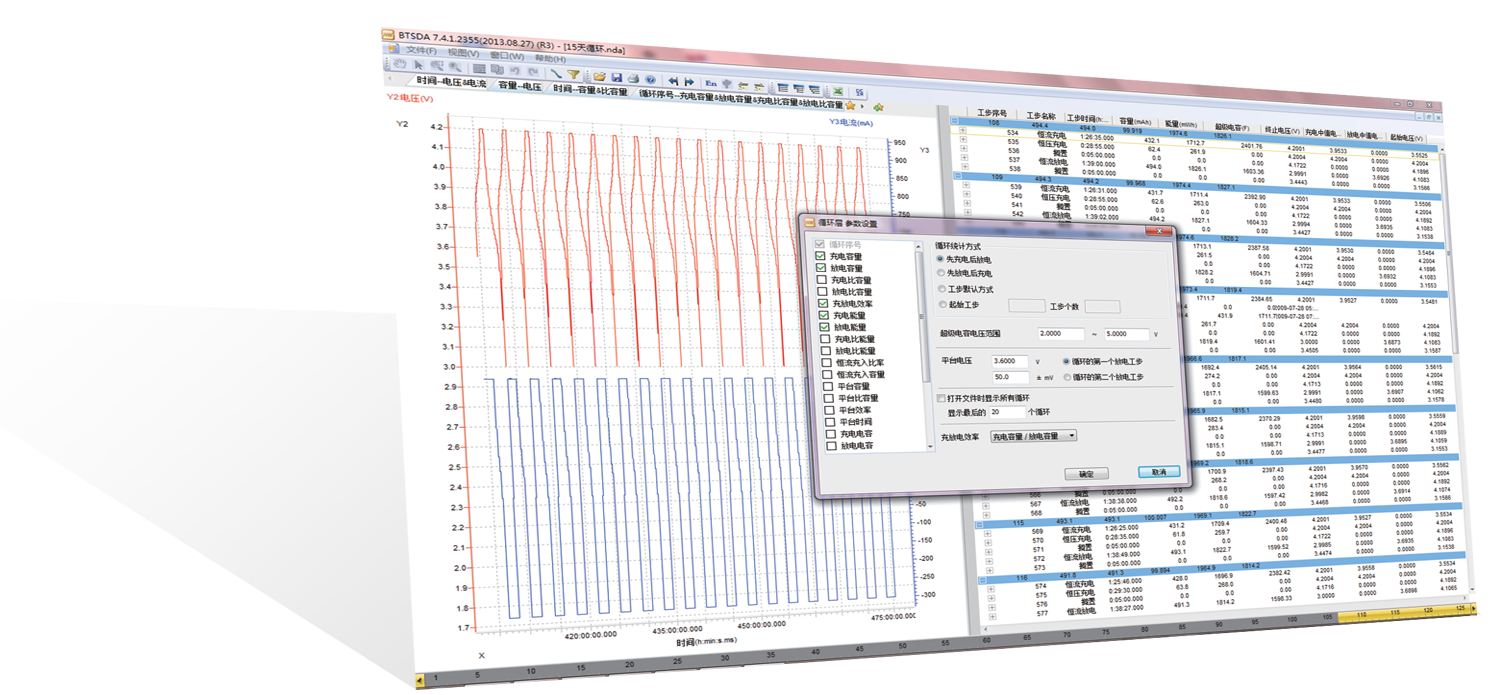

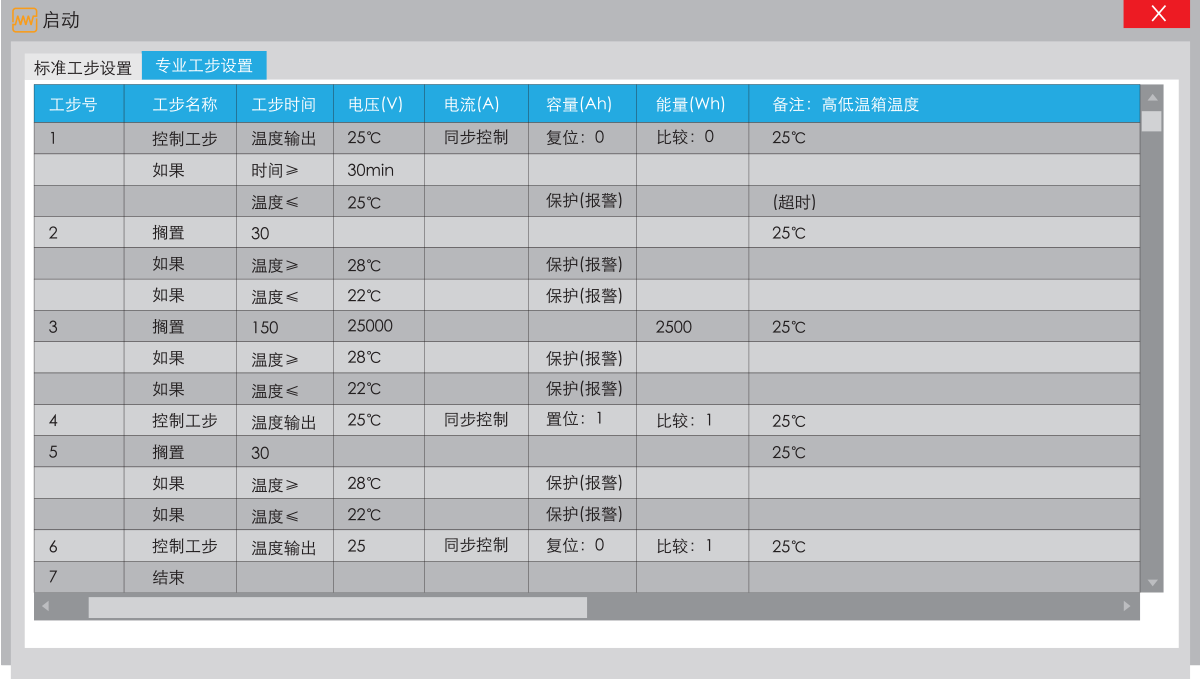

Conditions Switches

Battery testing steps need to be estimated for several conditions according to different operations during testing applications; Conditions switches meet requirements for multi-exits programming types.

“And””or” logic operation, “≥”, ”≤”, ”=” comparatively calculate; Time duration ”t”, can achieve control requirements for special testing. Every step supports 5 condition switches; Support multi-exits, go to any steps, achieve more flexible process control.

“And””or” logic operation, “≥”, ”≤”, ”=” comparatively calculate; Time duration ”t”, can achieve control requirements for special testing. Every step supports 5 condition switches; Support multi-exits, go to any steps, achieve more flexible process control.

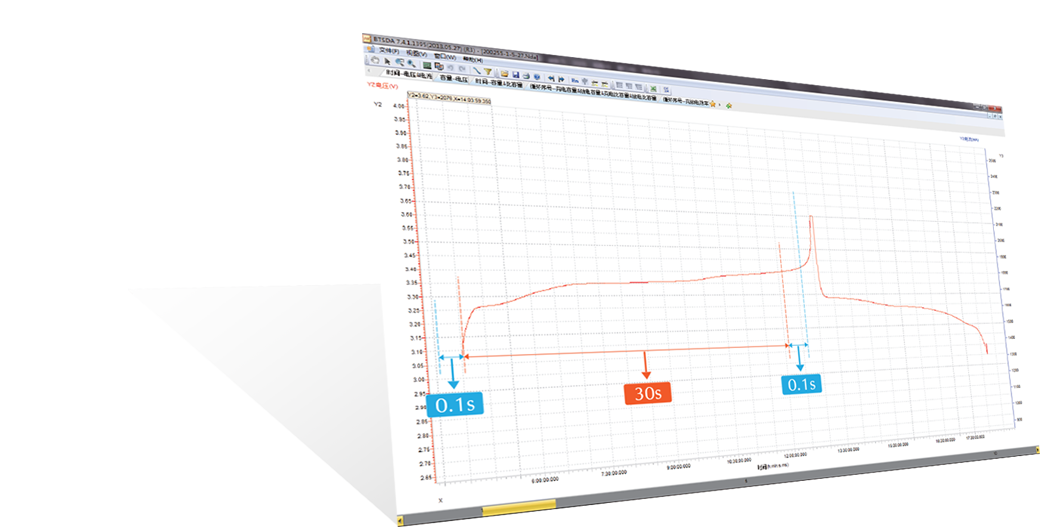

Segment-Record Conditions

Data record settings for voltage, current and time are supported;

3 segment-record conditions can be set for each step;

Every segment can be set: ΔT, ΔV and ΔI.

3 segment-record conditions can be set for each step;

Every segment can be set: ΔT, ΔV and ΔI.

EDLC Testing

The unit of Q is Coulomb, 1 Coulomb = 1A * 1s = 1As;

1Ah = 3600 As(Amp Second);

Work voltage U = Charge upper limited voltage - Discharge bottom limited voltage;

Working voltage can be set and the EDLC coulomb could be calculated automatically by the software.

1Ah = 3600 As(Amp Second);

Work voltage U = Charge upper limited voltage - Discharge bottom limited voltage;

Working voltage can be set and the EDLC coulomb could be calculated automatically by the software.

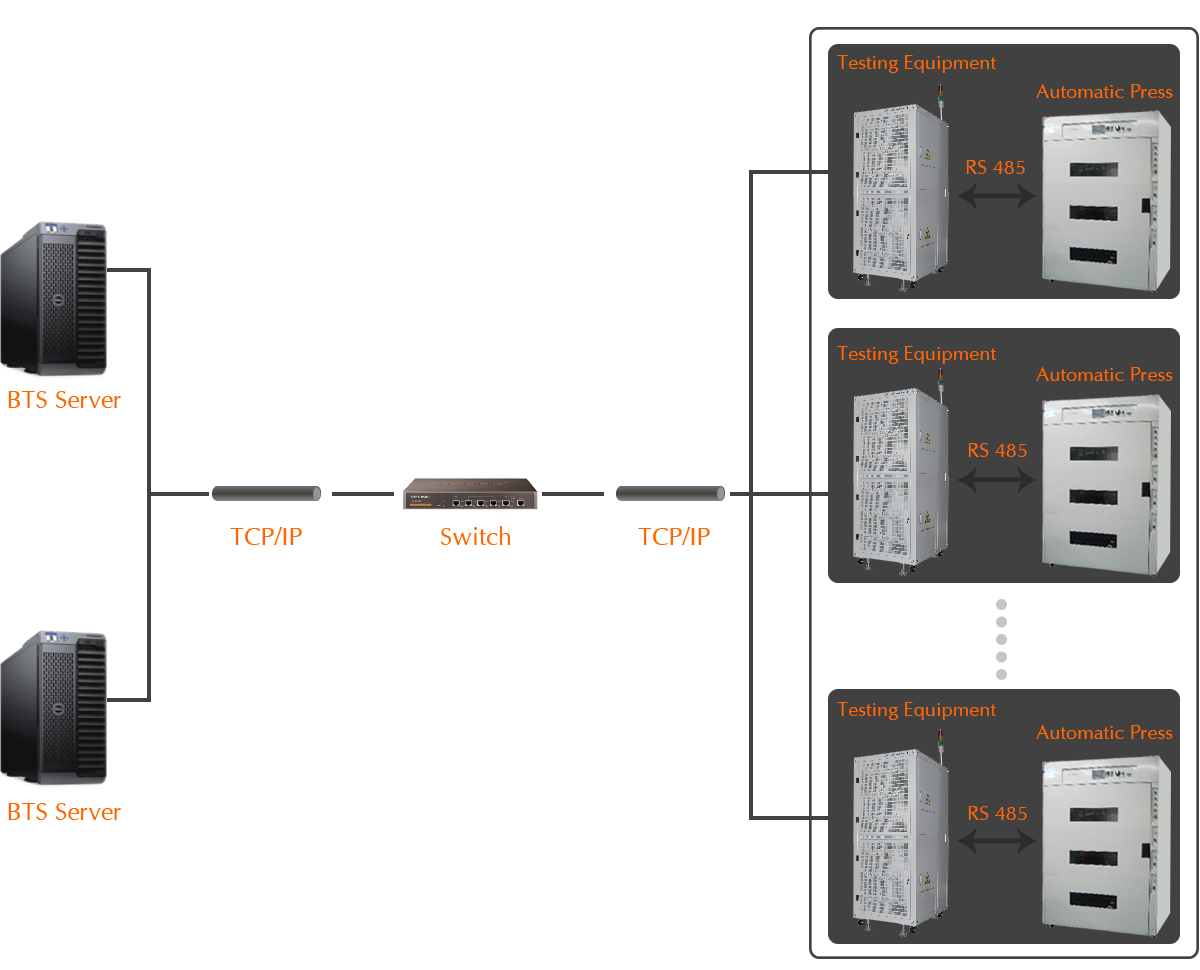

Control peripheral equipment by communication

BTS Server come true the peripheral equipment (Battery tester & Automation) communication control via switch.

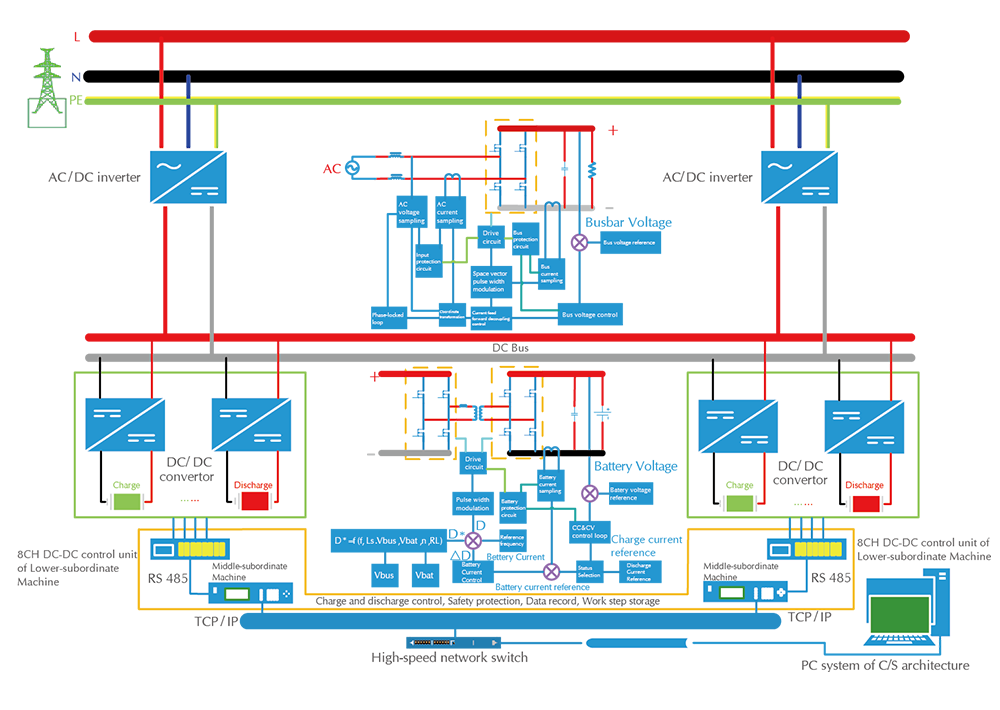

System Architecture

live:.cid.d7553a84e2f43ba0

live:.cid.d7553a84e2f43ba0

Global - English

Global - English